Over the last 76 years, hundreds of organizations have trusted us to help them identify and solve the complex business challenges that are preventing their organizations from reaching its full potential. Through a blend of development programs, coaching, assessments, and consulting services, our team partners with you and your organization to ensure you’re solving the challenges that are having the most significant impact on your organization. One of our partners, Quartz Health Solutions, has used continuous improvement programming to engage employees, increase quality scores, and save millions of dollars.

The Business Challenge

After the first successful merger with Unity Health Insurance and Gundersen Health Plan, Quartz Health Solutions recognized the need to review business processes throughout the new, combined organization. This was a critical step to ensure the organization could continue to scale and still serve their members, providers, and community with the best service possible.

The team at Quartz had a significant amount of manual work occurring throughout the organization, which was exacerbated by the merger. Post-merger, Quartz quickly identified the need to evaluate processes that had been merged from the two legacy systems into one, cumbersome process. For the organization to grow, processes needed to become sustainable, scalable, and efficient. The team knew this wasn’t something they could handle on their own and began to look for an external partner.

The Solution

Emily Murphy, program manager, process improvement, attended programming with the Wisconsin School of Business Center for Professional & Executive Development (CPED) and knew the organization would be an ideal partner to help Quartz design a continuous improvement program.

The focus of the program was to help the organization create a sustainable continuous improvement process that reduced internal and external costs, improved service, and created greater employee and customer satisfaction.

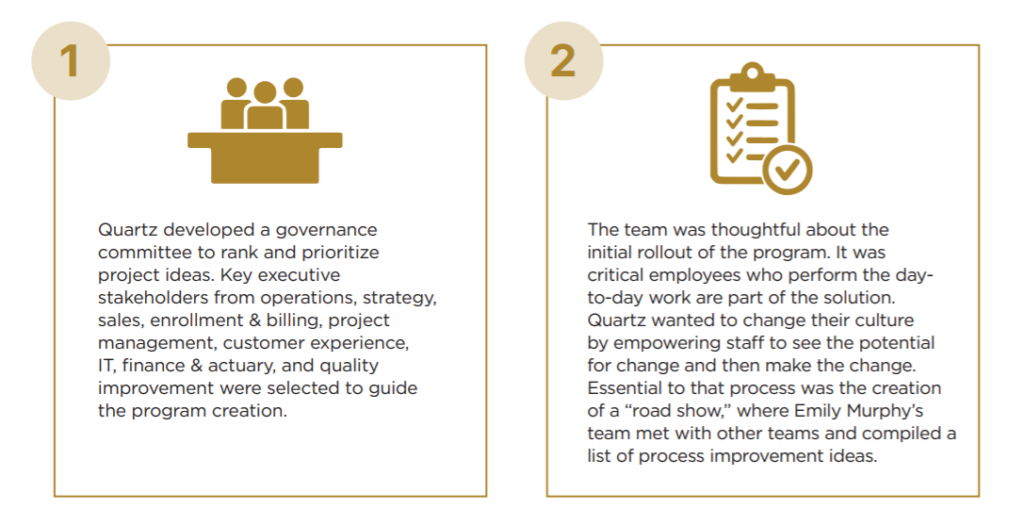

The program was built on two critical components:

- Obtaining senior leadership understanding and sponsorship for resources needed to do project work

- Ensuring that project scoping is an iterative process that can benefit from the expertise and support of either an internal, process improvement leader, or the support of an external resource.

Prior to developing the programming, CPED instructor and process improvement expert Scott Converse was brought in to provide an executive-level training to ensure leaders understood and found value in the methodology. Together, they began developing of a Lean Ecosystem, which included educating staff on Lean Six Sigma methodology. This was done in several ways:

Emily’s team built an internal program for employees who wanted to learn basic Lean Six Sigma concepts. A key goal for Quartz was for 75% of the organization to be trained in some level of Lean Six Sigma by 2022. Today, they’ve achieved 55%, and 88% of departments had team members participate in a Lean Six Sigma project or Kaizen Event.

Another unique aspect of the program is the partnership with Scott Converse, who co-designs Quartz-specific training sessions to showcase how the organization applies the methodology and framework to internal projects. This customization helps employees understand they have internal support and shares specific examples of how Quartz implements the methodology. Not only does this provide practicality, but it also increases engagement. They also developed a Lean Six Sigma communication campaign and developed control plans sponsored by the project’s executive stakeholder for all projects.

Results

Quartz and CPED have been growing this program for three years, and Quartz has experienced excellent results. They increased quality scores, reduced process times, and achieved a significant return on investment, saving the company millions of dollars. Quartz has also seen increased employee engagement. Employees are responsible for determining the solution for their challenges, so there’s a strong sense of ownership. It’s also provided development opportunities for employees from almost every area of the company.

“This program has even led employees to totally shift careers! One of the employees on my team was formerly an executive assistant when she took the yellow belt program. After seeing how the projects impacted the organization, she found a new calling. When we posted new positions to support the program, she applied and made the leap to lead process improvement initiatives. Having the ability to drive positive change throughout an organization is extremely rewarding.”

Emily Murphy, Program Manager, Process Improvement

To find out more about Quartz’s Lean Six Sigma program, download the case study. Your organization faces its own set of unique challenges and opportunities, and our team of Solutions Advisors is here to understand your organization’s needs and help you move forward. Set up a Discovery Session to learn how you can solve your current challenges while building the internal capability to solve future challenges with confidence.